Though invisible, embedded systems are all around us – from microwaves and washing machines to automotive braking control systems and fitness trackers. The global embedded systems market is projected to reach US$283.90 billion by 2034, with a CAGR of 4.77%.

Industrial control and automation dominate embedded system projects (29%), followed by IoT (24%), communications (21%), and automotive (19%). Other significant sectors include consumer electronics, medical devices, and AI-based applications.

As you see, embedded systems are widely used across domains where even a tiny mistake can cause safety hazards, financial losses, downtime, or regulatory issues. That's why efficient embedded testing is paramount for eliminating these serious troubles and ensuring high quality and reliability.

What is embedded system testing?

Embedded system testing validates the correct operation process that combines hardware and software to perform a specific function within larger mechanical or electrical systems.

The testing process covers both functional and non-functional aspects of embedded systems. While the former checks if a system operates flawlessly and as expected, the latter focuses on validating performance, security, reliability, compliance, etc.

Due to the unique nature of embedded systems, QA and software testing also take into account their key features – hardware-software integration, resource constraints, low power consumption, and real-time responsiveness.

Hardware-software integration: Embedded systems are defined by the tight coupling of software with specific hardware.

Even if software works well in a simulated or development environment, it might behave differently on actual hardware due to timing, pin-level dependencies, or hardware interrupts.

Any mismatch in communication between components can cause system failures.

Hardware-software integration testing is critical when it comes to industrial automation equipment, robotics, medical devices, etc.

Verifying correct software interaction with hardware drivers and peripherals

Ensuring proper execution of time-sensitive operations

Using hardware-in-the-loop (HIL) simulation to mimic real-world conditions

Hardware signals aren’t recognized by firmware

Malfunctioning peripheral initialization

Data corruption due to timing mismatches

Resource constraints: Embedded systems often run on constrained RAM, CPU, storage, or bandwidth.

Resource overflow can crash the entire system.

Inefficient use of memory or processing power leads to sluggish behavior or power drain, which is unacceptable for wearables, medical monitoring devices, smart appliances, etc.

Memory usage analysis

CPU load profiling under different workloads

Code footprint and optimization checks

Static code analysis for memory misuse detection

Unoptimized loops or function calls

Memory fragmentation

Inadequate buffer sizes

Low power consumption: Embedded systems are optimized for energy efficiency, making them ideal for battery-powered or energy-critical devices.

Power-hungry systems reduce product usability and fail to meet battery-life promises.

Devices must enter and exit low-power modes reliably.

Measuring power consumption in various states: active, idle, sleep

Verifying correct transitions between power modes

Simulating worst-case energy scenarios

High idle power draw

Missed sleep mode transitions

Unnecessary peripheral activation

Real-time operation: Most embedded systems must respond to events or inputs within strict deadlines.

A correct but late response can be catastrophic in critical systems like automotive braking systems or industrial robots.

Response time under load

Interrupt latency and priority handling

Deadline adherence and jitter

Task starvation or priority inversion

Slow ISR handling

Scheduling conflicts in RTOS environments

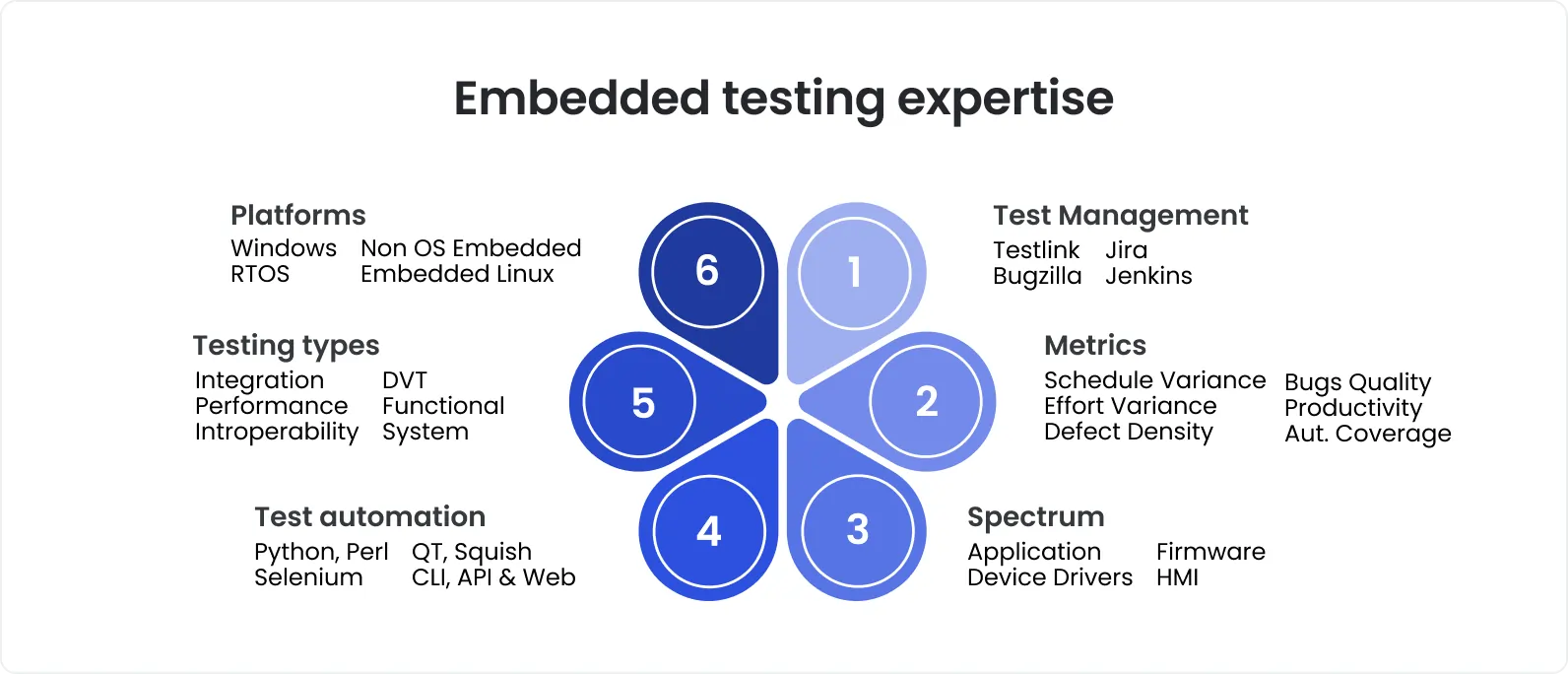

Testing embedded software is a far cry from testing general-purpose software. It requires specialized skills, deep technical expertise, and dedicated tools, all of which QA outsourcing brings to the table.

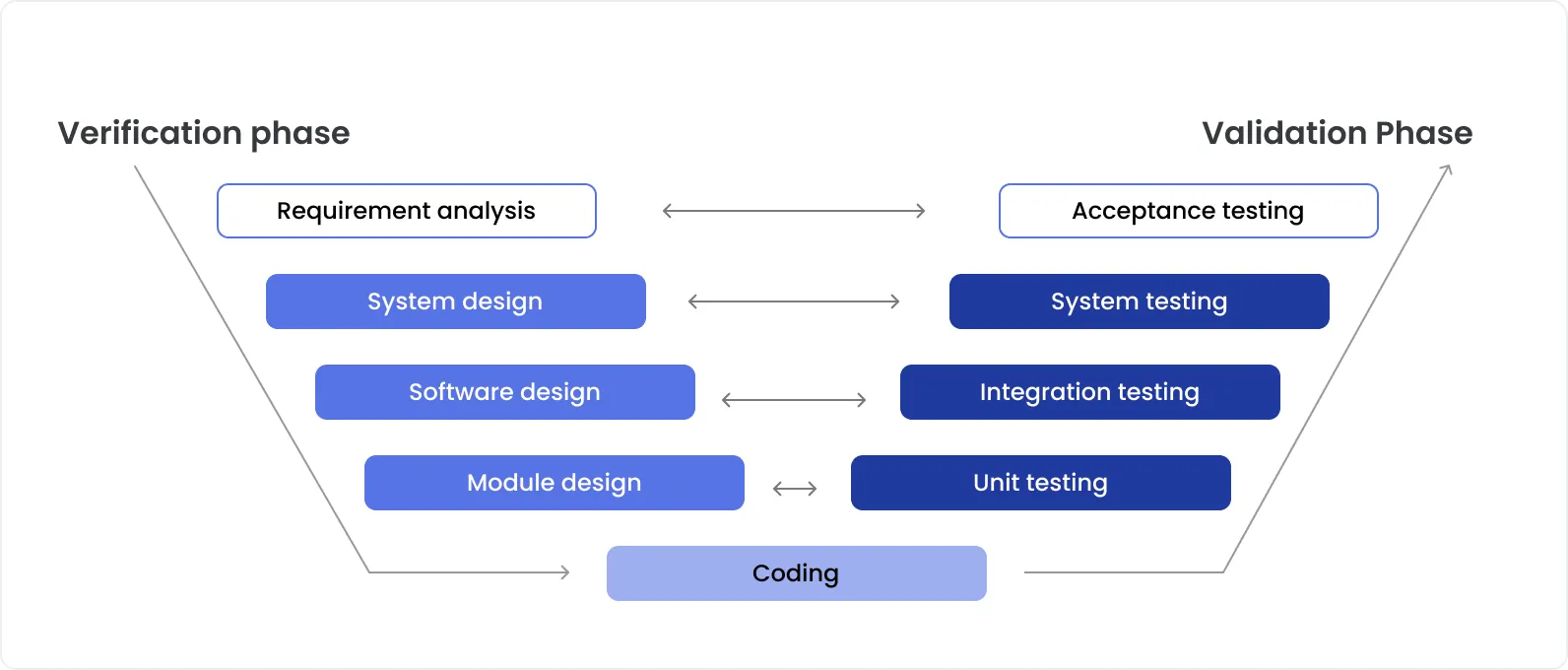

Testing levels relevant for embedded systems

Testing for embedded systems requires a layered, comprehensive approach that checks not only software functionality but also its interaction with hardware components under real-world constraints. Thorough embedded system validation suggests executing tests at well-known levels – unit, integration, and system.

Unit testing

Unit testing verifies the smallest testable components of embedded software – usually C/C++ functions, classes, or modules. To ensure proper testing, these units are isolated by abstracting dependencies on hardware behind interfaces or by using mock objects or stubs.

Let’s say firmware for a battery management system is developed. In this case, a unit test might check a function of the remaining charge calculation based on voltage levels. Instead of using a real voltage input, a QA engineer would leverage a stub function returning predefined values to validate logic in isolation before using physical hardware.

What tools can be used for embedded unit testing? Two of the most widely adopted frameworks are Unity and CppUTest.

Integration testing

Integration testing checks interactions between modules of embedded software and between software and hardware. This is of utter importance because the work of embedded systems depends not just on software logic, but also on the well-synchronized interactions with hardware components.

In embedded environments, integration testing has unique complexities, including the following:

Timing and synchronization

Embedded systems often work under real-time constraints. In other words, interactions must occur within strict time frames. During integration testing, artificial test environments might mask these issues, leading to surprises later during real-world operation.

Hardware dependencies

A software module might function perfectly when tested against a simulated peripheral but fail when integrated with the real hardware due to differences in timing, voltage levels, or protocol quirks.

Limited observability

Embedded systems have restricted output capabilities, because of which it’s difficult to monitor internal states without introducing intrusive debugging tools that themselves can alter system behavior. Resource constraints can also cause integration failures not evident during isolated module tests.

System-level component testing

System-level component testing validates major subsystems on their own before they are tied into the full system. The objective is to make sure each subsystem works exactly as needed so that when everything is integrated together later, problems do not snowball.

The recipe for effective system-level component testing is the isolation of the subsystem under test from the noise of the rest of the system. For this, we use mock interfaces, harnesses, or test boards that take full control over inputs and monitor outputs.

Another important aspect of system-level component testing is the right balance between simulation and physical testing. You have to do both, knowing when to lean more toward one or the other. Simulation works well in the early phases when hardware is unavailable yet or when running extensive tests on physical hardware would be too risky or time-consuming.

But simulation alone is never enough. Testing on physical hardware catches things simulations miss – things like connector tolerances, EMI interference, thermal coupling effects, sensor noise, and real-world wear and tear.

We usually aim for simulation to handle about 70-80% of the verification early on, giving us speed and broad coverage. Physical testing kicks in when hardware is stable enough to trust. It focuses on real-world behavior, stress testing, and fine-tuning.

Full system integration testing

Full system integration testing suggests verifying the combination of all subsystems previously tested in isolation to make sure the system as a whole works seamlessly under real-world conditions.

For example, testing a wearable device would include simulating a user powering on the device, connecting to a mobile app, reading sensor data, sending that data over Bluetooth, and handling incoming notifications. It’s important to check the work of the system not only under ideal conditions but also under edge cases and stress situations. The system might be run at low battery, with a weak wireless signal, and while performing CPU-intensive tasks.

One of the key challenges of full system integration testing is managing complexity. Now, you handle dozens of inputs and outputs of multiple subsystems. Tracing failures becomes difficult because symptoms might show up far away from the root cause. A brief brownout in the power rail could corrupt memory, and the consequences become visible hours later when corrupted data is finally accessed. To tackle this, detailed logging, event tracing, and error detection and reporting mechanisms inside the system are used.

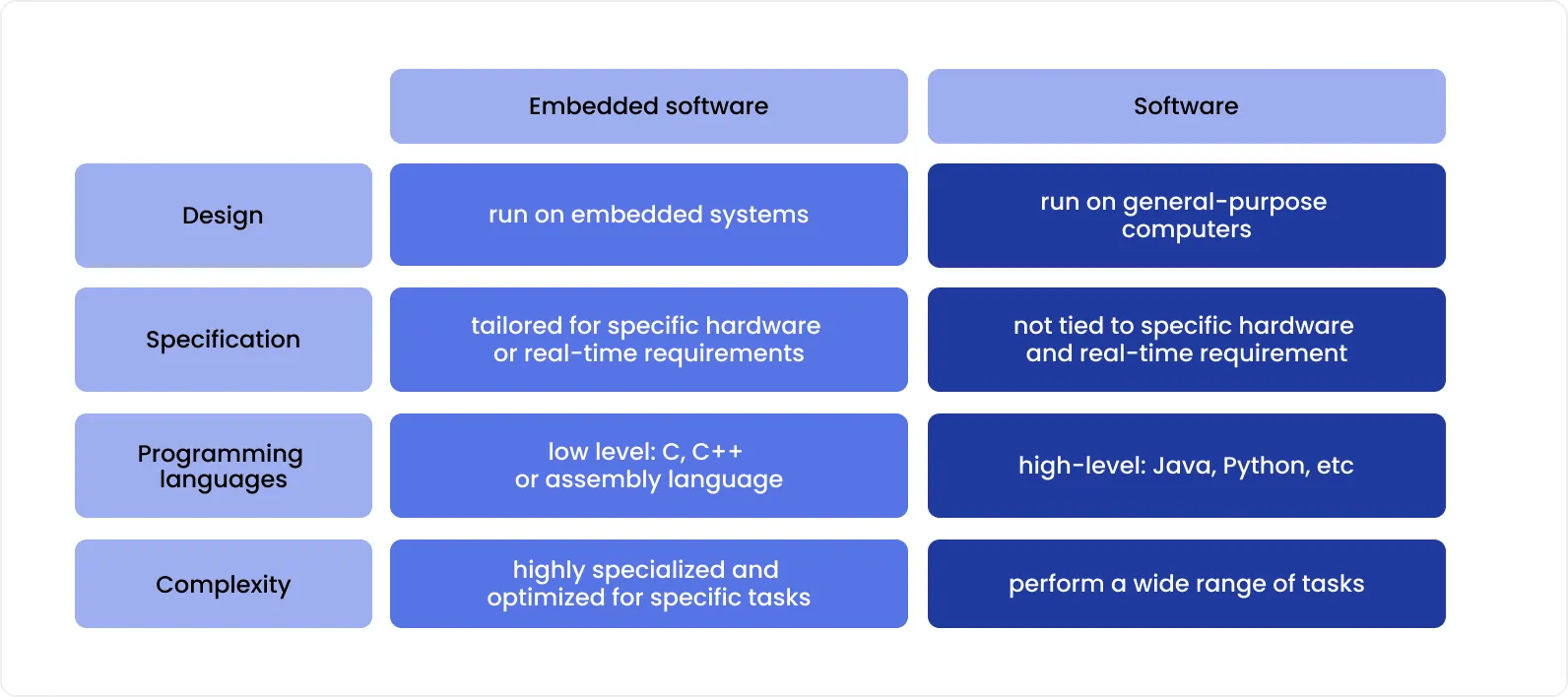

Embedded testing vs. general-purpose software testing

Embedded software and general-purpose software represent two distinct domains in the software development landscape, each requiring specialized testing approaches. While both aim to deliver reliable, functional software, the fundamental differences in their environments, constraints, and purposes create unique testing challenges.

While sharing the same fundamental QA principles and following the same goal, embedded system testing and general-purpose software testing differ significantly in techniques, approaches, risks, challenges, complexity, automation level, and other nuances. The table below demonstrates the differences you need to know.

Scope of testing

Testing both software and hardware to ensure their smooth integration.

Focusing solely on software applications.

Hardware dependency

High. Physical components like sensors, actuators, and microcontrollers are involved.

Low. Usually, testing is independent of specific hardware.

Environment

Tests are executed on target devices or simulators.

Tests are usually executed in software-based or cloud environments.

Tools

Specialized tools like oscilloscopes, HIL simulators, emulators, and debuggers are leveraged.

Standard software testing tools (e.g., Selenium, Postman, JUnit) are used.

Complexity

Testing is more complex due to hardware-software integration and real-time constraints.

Testing is simpler, as it covers software logic only.

Automation

Automation is more challenging because of the dependency on hardware. Yet, embedded software testing tools, HIL testing, SIL, and MiL simulations facilitate automated testing.

There is high potential for automation.

Cost and time

It’s often more time-consuming and costly because of manual and hardware testing.

It can be less costly and faster thanks to automation.

Failure Impact

High – failures can lead to hardware malfunction or safety risks.

Usually, low — issues may degrade user experience but are not life-threatening.

Debugging approach

Debugging is often done via hardware interfaces and requires device-level insight.

Debugging is usually done through logs, IDEs, and remote debugging.

As you can see, embedded system testing is more comprehensive, covering both hardware and software. It is also more complex, dependent on hardware, and often more costly due to physical hardware involvement.

Dedicated QA team that specializes in general-purpose software testing only lack the necessary expertise to deliver quality testing services for embedded systems. We strongly recommend bringing in professionals with hands-on experience in embedded testing. That’s paramount as the stakes are high.

Step-by-step guide to embedded testing

Embedded testing needs to be carefully structured and well-organized. Therefore, at a high level, we can break it down into four phases:

1. Laying the right foundation in the planning phase

Before springing to active testing, we define what success looks like exactly. We collaborate with all the stakeholders to gather available system requirements, including functionality, acceptable failure modes, performance thresholds it needs to meet, etc.

We outline clear testing goals, identify critical components, define possible risks, and map out where hardware meets software. From there, we create a suite of test cases that cover expected behavior, critical edge cases, and key integration points where problems are more likely to appear later.

2. Building the right environment in the setup phase

Once the plan is ready, we move to the environment setup. The right tool choice and proper configuration are half the battle. Depending on the system, this phase might include setting up a Hardware-in-the-Loop (HIL) environment and configuring power analyzers, oscilloscopes, test harnesses, or JTAG debug tools.

Rich experience lets us clearly understand when it makes sense to build a full test rig and when a software simulation can save time and effort while still delivering reliable results.

3. Challenging the system in the test execution phase

Repeatability and traceability are at the core of our testing approach. That's why each test run contains logs, timestamps, conditions, and results. Our QA engineers log the environmental conditions alongside test outcomes.

Tests, especially repeatable ones, are automated whenever feasible and relevant. Real-time dashboards demonstrate pass/fail trends, helping us spot unusual behaviors early before they require costly rework.

4. Gaining insights in the analysis phase

When the test run is finished, we study logs, detect anomalies, correlate them with test conditions, and conduct root cause analysis.

When reporting issues, we also suggest practical fixes or design adjustments based on patterns we’ve seen in other projects.

Tests critical for embedded systems

Now that you’ve got the big picture, we offer to take a closer look at the types of tests essential for embedded systems and the tools that facilitate their execution.

Functional testing

Let's start with functional testing that verifies if all the components and features of embedded systems work as they are supposed to, i.e., as specified by functional requirements.

Tools to use:

Robot Framework is a tool you need for high-level functional and system testing of embedded devices. It automates complete device workflows, simulates user actions, and verifies system responses.

Pytest is used in combination with custom libraries for writing flexible functional test suites around hardware interfaces.

Vector CANoe/CANalyzer is a good choice for functional and communication testing.

Interface testing

The fact that embedded systems often interact with external devices or other subsystems necessitates thorough testing of the interfaces between components. This involves testing communication protocols and interfaces like serial links, wireless connections, Ethernet, or other networking protocols.

Tools to use:

Bus Hound and Saleae Logic Analyzer are leveraged to analyze communication protocols like SPI, I2C, or UART.

Wireshark is a good option for testing Ethernet or wireless communication protocols.

CANoe is used for CAN bus testing and simulation.

Real-time testing

Embedded systems often require real-time operation, due to which timing is critical. Real-time testing ensures that the system meets its timing constraints and responds within the stated time limits.

Tools to use:

Tracealyzer helps with analyzing real-time system performance and tracing software behavior.

JTAG debuggers enable timing and latency analysis of embedded systems.

RTOS tools trace functionality for real-time task scheduling analysis.

Power and energy consumption testing

As mentioned above, power consumption is one of the key concerns for many embedded systems. Testing of that kind lets engineers understand if a system operates within acceptable limits.

Tools to use:

Keysight Power Analyzer or Tektronix Power Analyzer is used to measure current and voltage across components.

Monsoon Power Monitor is suitable for testing low-power devices in real-world scenarios.

Battery simulators help to test power behavior under different charging and usage conditions.

Stress testing and load testing

Performance testing checks how the system works beyond its normal operating conditions by exposing it to extreme stress.

Tools to use:

LoadRunner and JMeter simulate high traffic and network load.

IxChariot is used for network stress testing in embedded systems that rely on Ethernet or wireless communication.

Environmental testing

Far too often, embedded systems are used in particularly harsh environments, so it’s paramount to ensure their flawless operation under different environmental conditions.

Tools to use:

Thermal chambers are leveraged for high- and low-temperature testing.

Vibration testers, like IMV or ESPEC, simulate mechanical shock and vibration.

EMC/EMI testing equipment, like Rohde & Schwarz, enables electromagnetic interference and compatibility testing.

Security testing

Security testing is increasingly important in embedded systems, especially those connected to networks. It’s indeed essential to check the system for security vulnerabilities to ensure its resistance to possible attacks.

Tools to use:

Wireshark and Burp Suite are perfect for network security testing and vulnerability scanning.

Coverity and Klocwork are static analysis tools that identify code vulnerabilities.

AFL and Peach Fuzzer are fuzzing tools used to test for unexpected behavior or crashes in case of unusual input.

Safety and compliance testing

Most embedded systems must comply with relevant industry standards. Safety and compliance testing ensures that both software and hardware meet strict reliability, fault tolerance, and risk management requirements.

Tools to use:

MathWorks Simulink is used to model, simulate, and test control algorithms in systems that must meet standards such as IEC 61508 (functional safety for general electronic systems), ISO 26262 (functional safety for road vehicles), and DO-178C (for aviation).

A-SPICE is a framework for assessing software development processes in automotive projects.

PC-lint is used for deep static C/C++ code analysis to uncover safety issues, MISRA rule violations, and runtime-like defects without code execution.

Overcoming common challenges of embedded testing

It’s time to talk about less pleasant but still important things – the challenges that inevitably come up during embedded testing.

Limited hardware access

One of the biggest hurdles, especially in the early stages of embedded system testing, is the lack of access to real hardware. It may still be under design, stuck in procurement, or limited to just a couple of prototype units. As a result, testing may grind to a halt because there’s nothing physical to test it on.

To avoid delays, we make active use of HIL testing, hardware simulators, and emulators that let us start validating business logic, communication flows, and peripheral behavior long before hardware is available.

Constrained resources

Embedded systems usually operate in severe conditions. Whether it’s a medical sensor or a control module in an electric vehicle, QA engineers often deal with tight CPU budgets, kilobytes of RAM, and strict power constraints. Writing and running full-scale tests directly on the device can easily interfere with system performance or, even worse, make it unusable during testing.

At DeviQA, we reduce on-target test overhead by keeping embedded test logic ultra-light and offloading as much testing as possible to the host. Using unit testing frameworks like Ceedling and GoogleTest, we isolate and validate critical functions on a desktop or CI server, saving device resources.

Difficult defect reproduction

In embedded systems, many bugs show up only under very specific timing conditions, power fluctuations, or environmental triggers, making it rather difficult to replicate bugs. It can take days to track down a communication failure that happens once every few thousand messages or a watchdog timeout caused by a rare interrupt collision, especially if the conditions can’t be reliably recreated.

To handle this efficiently, our team always builds in detailed logging and diagnostics from day one. Also, we use trace buffers, real-time monitoring, fault injection, and HIL testing to quickly capture and reproduce elusive bugs.

Specialized knowledge requirements

Embedded QA requires a deep understanding of software and hardware. Test engineers need to know their way around memory-mapped registers, real-time constraints, peripheral behavior, and many more. This unique skill set isn’t always easy to find or scale within teams.

Fortunately, outsourcing provides a good solution. Partnering with experienced providers like DeviQA allows businesses to quickly onboard QA specialists who are well-versed in embedded systems testing. Whether through an outstaffing model or a dedicated QA team, we help our customers ensure the outstanding quality of their embedded systems.

The role of Hardware-in-the-Loop (HIL) testing

Throughout the article, we mentioned HIL testing several times. However, it deserves more attention because of the critical role it plays in testing embedded systems.

Hardware-in-the-Loop (HIL) testing is a complex technique that enables the validation of software and hardware interactions within a controlled, real-time environment. By integrating actual hardware components with simulated models of the surrounding system, HIL testing facilitates comprehensive evaluation without the need for all physical prototypes.

In a Hardware-in-the-Loop (HIL) setup, the system under test is connected to a simulator that mimics its real-world operation environment, usually named 'plant.' The simulator sends inputs to the system and receives its outputs, creating a two-way, real-time interaction and enabling safe and controlled testing.

In the automotive sector, for example. HIL testing can simulate vehicle behavior and road conditions to test the work of ECUs responsible for braking and steering in various driving scenarios.

HIL plays a significant role in embedded testing due to enabling early validation. The accurate simulation of operational environments allows QA teams to uncover bugs long before physical hardware is available. This, in turn, saves a lot of time and reduces costs. Moreover, HIL testing improves safety by enabling the simulation of hazardous conditions without a risk of damaging physical components or endangering personnel.

Wrap-up

Embedded QA is a demanding discipline. The testing process is both time- and effort-intensive, while a single overlooked error can cost a human life since embedded systems are often integral to medical, automotive, defense, and aerospace equipment.

Such peculiarities of embedded systems as dependency on hardware, constrained resources, low power consumption, and real-time operation impose additional challenges for QA engineers. Therefore, testing embedded software differs significantly from testing common software. It requires specialized expertise in embedded software testing techniques, software-hardware integration, HIL testing, and many more.

To gain the required skills, hands-on experience is needed. At DevQA, we have it and are always ready to share our knowledge and expertise to help our customers ensure the outstanding quality of their embedded systems.